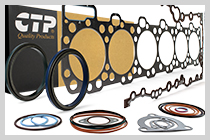

Search and buy New Replacement Caterpillar® Parts and Replacement Komatsu® Parts, equipment and engines. You can search by category, part number or serial number to find the parts you need. You can request a quote online. Our sales team is attentive to help you.

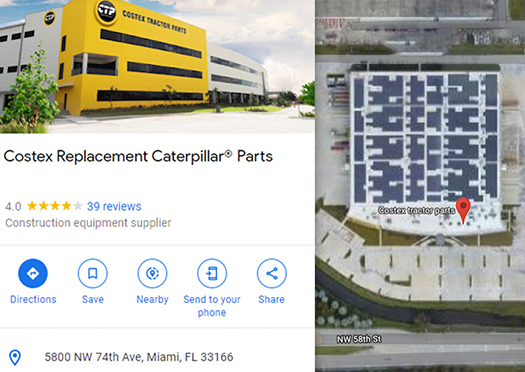

Miami Headquarters:

5800 N.W. 74th Ave

Miami, Florida 33166

Tel: (305) 592-9769

Toll Free in USA: 1 800 321-2451

Subscribe to our Insidetrack Mailing List

NEWS & EVENTS

M&T EXPO Tradeshow – 2024

CTP will be attending the M&T Expo 2024 Tradeshow. M&T Expo is the largest Latin-American trade show for construction and mining equipment. The event establishes itself as the most important environment of technological innovation and business in its segment. We will be there from April 23rd through 26th.

Miami Location:

© 2024 Costex Tractor Parts. All Rights Reserved. Terms of use & privacy | Sitemap

CTP® and Freddy the Filter® are registered trademarks of Costex Corporation. Cat® and Caterpillar® are registered trademarks of Caterpillar, Inc. Komatsu® is a registered trademark of Komatsu Ltd.

Visit CTP Boxes for your Custom Boxes.